PLASTICS AND BIOCOMPOSITES

FOR SUSTAINABLE DEVELOPMENT

We responsibly process plastics, recyclates and biocomposites. We use our expertise and experience for sustainable ideas and concepts. Ideally, we create a balance between ecological, social and economic interests.

Our Commitment

Plastics are on the one hand very versatile and extremely durable, on the other hand they are a great danger to our environment. However, a plastic-free world is incompatible with our society’s ideas of prosperity and fortune.

How do we solve this dilemma? Collectively!

We are committed to ensure that the era of plastic-use, in this mindless way mankind has dealt with, belongs to our past rather than our future and present as soon as possible.

Our mentality and actions are rooted in continuous improvements that take people and ecosystems into consideration, while focusing on the development, use, disposal or reuse of any product.

Ideally, we meet our customers to transform current challenges into new opportunities while protecting our planet at the same time.

OUR EXPERTISE

CONSTRUCTION INDUSTRY

CONSUMER GOODS

LAB EQUIPMENT

MEDICAL TECHNOLOGY

RAILWAY INFRASTRUCTURE

HOUSEHOLD GOODS …

SWK Innovations develops innovative and sustainable solutions for the application of plastics. We have an interdisciplinary approach and, together with our partners from science and business, we pursue the goal of preserving the advantages of plastic while reducing the disadvantages extensively.

Our employees are specialized in solving highly complex technical assignments.

SERVICES

CONSULTING

PRODUCT DEVELOPMENT

CONSTRUCTION

3D PRINT SAMPLING

CIRCULAR DESIGN

MOLD CONSTRUCTION

INJECTION MOLDING

2-COMPONENT TECHNOLOGY

EXTRUSION

MATERIAL DEVELOPMENT

This “one-stop-shop” principle ensures short development cycles, cost-optimized processes and product developments.

Biocomposites

Our customizable biocomposites are a compound of bio-based polymers and natural residues, which hereby gain an additional purpose. Amongst others these include wood flour, olive pits, hemp fibers or coffee chaff.

The use of bio-composite materials is an innovative and resource-friendly alternative to purely petrochemical or bio-based polymers. Biocomposites are more sustainable materials with a favorable CO2 balance. In combination with a biodegradable polymer matrix, biocomposites help to reduce or avoid microplastics altogether.

News

There can be highly demanding requirements for an IVD (In Vitro Diagnostics) product. SWK has developed a vacuum-tight, transparent sample container that is very easy to close and even passes the Container Closure Integrity Test after being frozen to -70°C. The tube has a mark for the maximum capacity of 5ml.

A self-developed and designed rack accommodates 96 sample containers in one tier and is designed to allow a process that can be performed quickly and easily using multichannel pipettes.

The Drip Drop Yo-Yo Grinder is a novelty invention straight from the top minds at Drip Drop HQ. Witness the combined excitement of Yo-Yo fun, fashionable design and the ability to grind your herb of choice. The Yo-Yo is made with an extreme focus on sustainability. Locally produced and assembled in Germany, made of bio-based polymers and wood fibers. Get ready to be the coolest cat at any social gathering. Unless somebody else also brought one, in that case we recommend a Yo-Yo Off (or trick competition for the laypeople). Order your Yo-Yo here

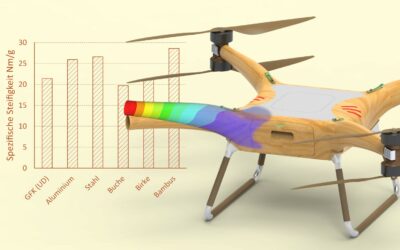

In the face of the rapid global economic development of the last decades and the associated problems of environmental degradation, resource exploitation and climate change, it is becoming increasingly important to create more sustainable products and economic models. The HerMes project will develop a multicopter system with a significantly improved sustainability record. Only suitable materials and manufacturing processes based on renewable raw materials are utilized. In particular, wood and natural fiber-reinforced bioplastics, convince with their excellent structural and mechanical properties as well as good recyclability and cost efficiency. Further information on the research project is available here.

In times of the coronavirus, know-how, flexibility and creativity are particularly in demand.

The SWK Innovations team has proven exactly this and developed, together with Centogene AG, a new throat swab swab to test for SARS-CoV-2 RNA and prepared it for it’s industrial production, in just 18 days. A quick turnaround on new customer demands is nothing new for SWK. As a hybrid company that offers everything from services such as the creation of first sketches to development and industrial production, SWK Innovations has a decisive competitive advantage: the entire know-how is readily available within the company – from picking up an idea to the necessary work and operating equipment. The throat swab swab is part of a fully validated test kit for the detection of SARS-CoV-2-RNA, which is offered worldwide by Centogene AG (www.centogene.com).

Photo credit: Centogene AG

Wallstreet Online press report

The CentoSwab is available here

Nager IT e.V. advocates for humane working conditions in the factories of the computer industry. Another concern is the environmental compatibility of the products. Nager IT is embarking on new paths with the materials they employ. Sustainability and thinking in cycles play a major role. The casing of the fair computer mouse is produced by SWK Innovations with post-consumer recyclate in an injection molding process. Particularly sustainable: All parts of the mouse can be replaced or repaired in the event of something being defective. That means, nobody has to throw out the fair computer mouse. More information about the fair mouse from Nager IT is available here: www.nager-it.de

Photo credit: Institute for Bioplastics and Biocomposites, Hannover

This is the slogan of the 8th Biocomposite Conference Cologne from November 14th to 15th, 2019. SWK will participate as a sponsor and with an exhibition booth! Amongst other things, we will showcase products made from biocomposites of coffee bean chaff, olive pits and almond shells, which are all produced in-house.

The Fachagentur Nachwachsende Rohstoffe e.V. is the project owner of the German Federal Ministry of Food and Agriculture and is represented at this year’s K trade show at Booth SC16 / Halle 7.0. In collaboration with the companies Arburg and Linotech as well as our circular designer Michael Neusüß, a giveaway was designed which will be distributed to interested visitors. The giveaway consists of a spiral cutter made of biocomposite that will be produced on-site, a color pattern sample, a brochure on biocomposites from SWK and Linotech and a road map of the product’s life cycle. We’d love to welcome many visitors!

“Let’s work together to make some difference to our planet” is the mission of GOODTHINKING, a SGOP brand: “Think Green. Design green. Make Green“. The company specializes in sustainable office supplies and operates globally. After completion of the injection molds in our workshop in mid-October, SWK will produce the first samples made of biocomposite, which will be showcased at the Canton Fair Autumn 2019, in China. SGOP will also be present at the Paper World in January 2020, in Frankfurt am Main, with biocomposite office supplies produced by SWK.www.goodthinkingoffice.com

SWK is a partner in a research and development project funded by the Federal Ministry of Food and Agriculture, in collaboration with a medium-sized company, advisory engineers and the fruit growing research institute York (Lower Saxony Chamber of Agriculture). The goal of the planned development is a new kind of frost protection and micro-irrigation in one single system that will represent an economic and ecological innovation in agriculture.

In collaboration with LUM GmbH, Berlin, SWK developed a very complex cuvette contour with an optical path length of only 1mm. This cuvette is utilized for the characterization of nano and microparticles as well as suspensions and emulsions. After the injection mold was completed by SWK, the cuvette series production was also finished in-house at SWK. They are now used globally in modern analysis instruments.

Contact

SWK Innovations GmbH & Co. KG

Am Wäldchen 23

03222 Lübbenau / Spreewald

Phone: +49 (0)3542 887080

Fax: +49 (0)3542 8870820

E-Mail: info@swk.berlin

Petra Stammberger | CEO / Managing Director

+49 (0)3542 8870829 | +49 (0)170 9211360

p.stammberger@swk.berlin

Thomas Psaar | CTO + Authorized Signatory

+49 (0)3542 8870811 | +49 (0)1511 6580180

t.psaar@swk.berlin